Flake Ice Temp: -5℃

Flake Ice Thickness: 1.5-2.2mm

Refrigerant: R404A/R22

Power Supply: 3P/380V/50HZ

Standard Condition: Ambient temp 25℃, Water inlet temp 18℃

Application Condition: Ambient temp 5-40℃, Water inlet temp 0-40℃

1. Features of flake ice:

A. Greatest cooling surface area---

Flake ice has more than 1,600 square meters of surface area per ton of ice, providing greater cooling efficiency than any other type of ice.

B. Faster cooling efficiency---

Flake ice thickness is about 1.5mm-2.2mm, the thin shape of flake ice allows it to melt quickly for the fastest heat transfer. Ice only cools when it melts, so faster melting equals faster cooling.

C. Greater product protection---

Flake ice remains dry, smooth, flat without any hard corners. These unique features make flake ice become the ideal cooing resource for food products cooling. Its flat shape will not damage the seafood surface and frozen food as well.

D. Easier storage and distribution---

Flake ice is completely dry, clean and free-flowing, it is not easy to clump and blends, so it will not fuse together in a storage bin or clog delivery systems. This is critical in high volume ice applications like seafood processing plants and concrete mixing plants.

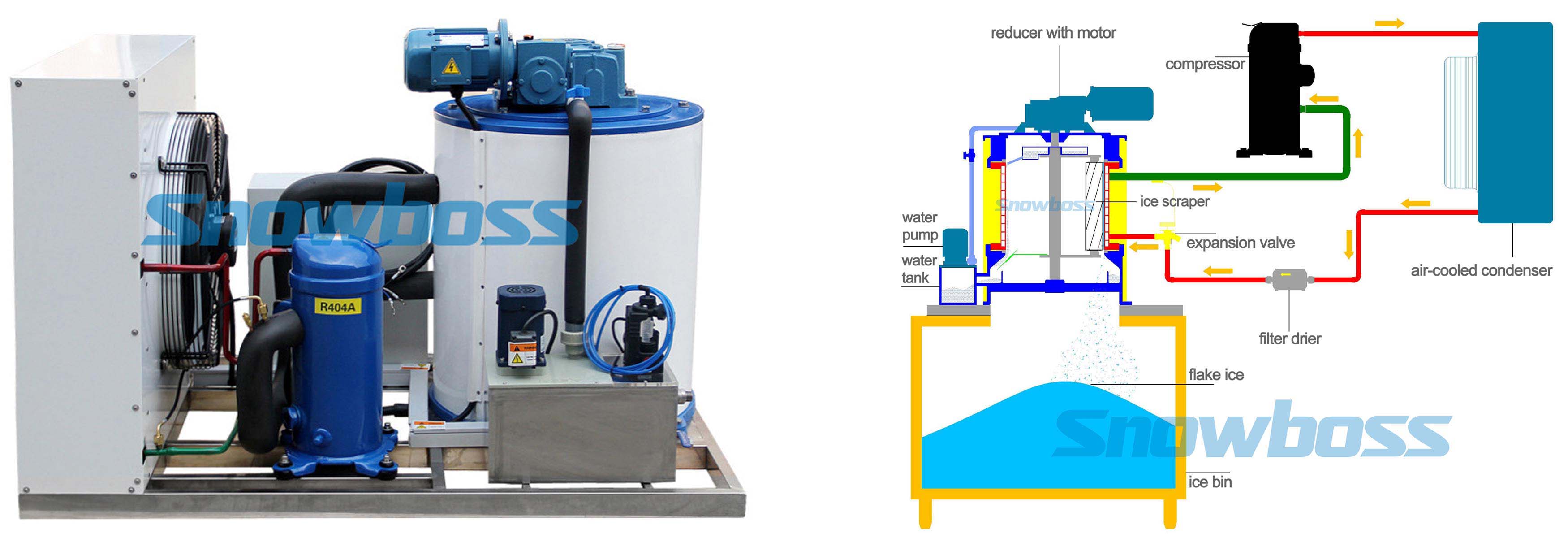

2. Working Principle of flake ice machine:

When the refrigeration system begins to work normally, the water in water tank is pumped into the water distribution pan by the water pump. Driven by the speed reducer, the water in the distribution pan evenly flows down to the inner wall of evaporator. The refrigerant gas inside the refrigeration system evaporates through the loop inside the evaporator and absorbs large amount of heat by exchanging heat with the water on the wall.

As a result, the water flowing over the surface of inner evaporator wall sharply cools down to below the freezing point and freeze into ice instantaneously. When the flake ice on the inner wall reaches to a certain thickness, ice scraper driven by the speed reducer will cut the ice off and then the flake ice will drop into the ice storage directly for later use. Some of water which did not freeze into ice will flow down to the water sink at the bottom of the evaporator and then back into water tank for recycling.

3. Features of flake ice machine:

A. Daily production of our flake ice machines range from 500kg/24hours to 50ton/24hours with full series of capacity for all kinds of applications.

B. Integrated modular design makes the flake ice machines easy installation, convenient operation and simple maintenance.

C. Main shaft, ice scraper, base frame, evaporator inner wall and outer wall are made of stainless steel material, internally-scraping ice blade can help to reduce energy consumption and prevent leakage of refrigerant gas.

D. Flake ice machines can be fitted with either an air-cooled condenser or water-cooled condenser, and refrigerant gas can be R404A, R507 and R22.

E. Fully-automatic control by using PLC controller, the flake ice machine will stop working automatically while the flake ice in storage bin is full as we installed infrared switch at the bottom of flake ice evaporator.

F. We use selected accessories from well-known brands, such as Bitzer, Danfoss, Copeland, Hanbell, ALCO, LS, Emerson, Schneider and so on, which make our flake ice machines high reliability and low breakdown rate.

4. Applications of flake ice machine:

Due to the above-mentioned characteristic and affordable costs, flake ice machine is widely applied in Medium and large chain supermarket, Seafood restaurant, Hotel, Fishery and Aquatic food processing, Food processing and storage, Fruit and Vegetable preservation, Meat processing, Poultry slaughtering, Ocean fishing, Bakery, Chemical industry, Medical industry, Mine temperature reduction, Men-made ski ground, Nuclear project, Concrete cooling project, etc.